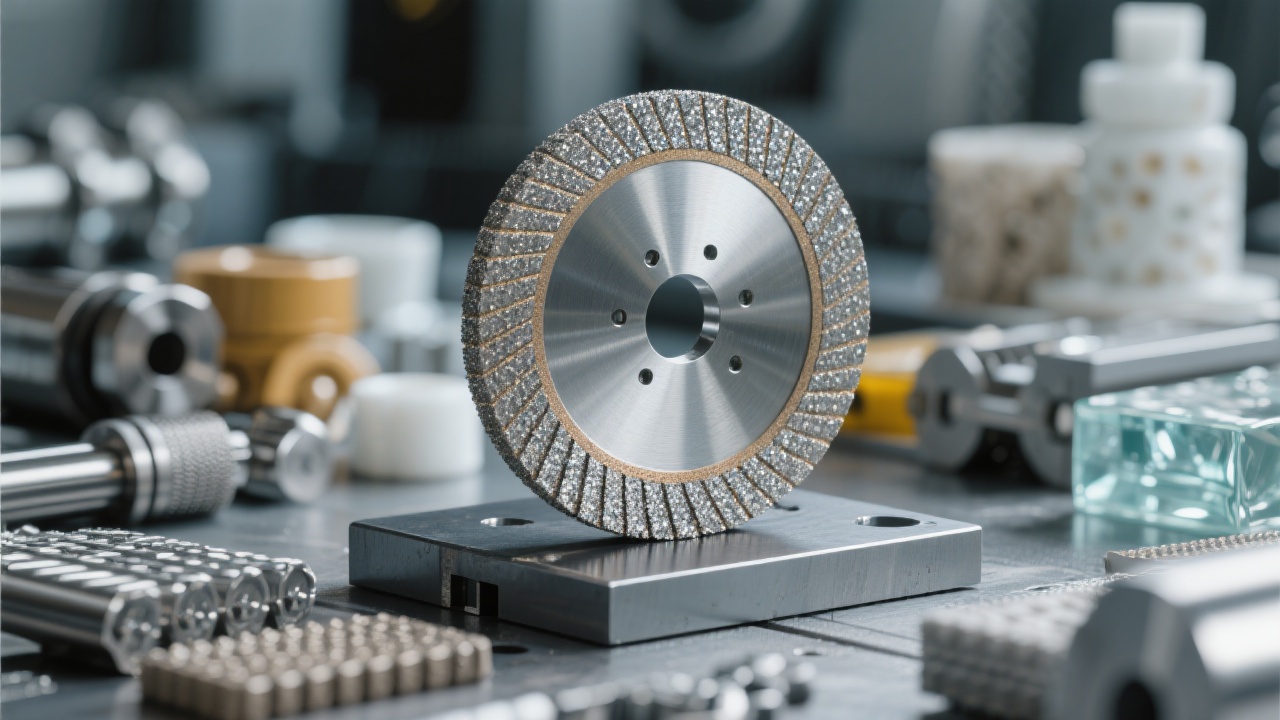

Selecting the right diamond saw blade is crucial for construction and metal - processing users. However, many users fall into common selection traps, which can lead to decreased cutting efficiency, higher costs, and potential safety risks. This article, based on industry experience and the technical advantages of the UDS010 diamond saw blade, aims to provide practical guidance on selection and operation.

One of the most common mistakes is not matching the saw blade to the cutting material. For example, using a saw blade designed for soft materials on hard metals can cause premature wear of the blade. According to industry data, incorrect material - blade matching can increase blade replacement frequency by up to 30%. Another error is ignoring the saw blade's grit size and diameter. A too - large or too - small diameter can lead to inefficient cutting, while an inappropriate grit size may result in a poor - quality cut surface.

When cutting soft materials such as wood or plastic, a saw blade with a larger grit size (e.g., 80 - 120 grit) is recommended. This allows for a faster cutting speed and a smoother cut surface. For hard materials like granite or stainless steel, a smaller grit size (e.g., 20 - 40 grit) provides better cutting performance. As for the diameter, for small - scale cutting jobs, a saw blade with a diameter of 10 - 12 inches is sufficient, while large - scale industrial cutting may require a blade with a diameter of 18 - 24 inches.

| Cutting Material | Recommended Grit Size | Recommended Diameter |

|---|---|---|

| Wood | 80 - 120 grit | 10 - 12 inches |

| Granite | 20 - 40 grit | 18 - 24 inches |

The cutting speed is closely related to the saw blade's design. A well - designed saw blade can maintain a high cutting speed while ensuring a long service life. For the UDS010 diamond saw blade, its unique tooth design and advanced manufacturing process allow for a cutting speed that is 20% faster than traditional saw blades. However, it's important to note that the cutting speed also needs to be adjusted according to the cutting material and the saw blade's diameter.

The UDS010 saw blade features a high - quality carbide chassis, which significantly improves the blade's stability and lifespan. The carbide chassis can withstand high - temperature and high - pressure cutting conditions, reducing the risk of blade deformation. Tests show that saw blades with carbide chassis have a service life that is 40% longer than those without.

Before starting the cutting operation, users should first check the saw blade for any damage or defects. Then, they need to install the saw blade correctly on the cutting machine, ensuring that it is tightly fixed. During the cutting process, users should maintain a stable cutting speed and apply appropriate pressure. The operation steps are as follows: 1. Check the saw blade; 2. Install the saw blade; 3. Adjust the cutting speed and pressure; 4. Start the cutting operation; 5. Stop the machine after cutting and remove the saw blade safely.

A construction company was facing high blade replacement costs and low cutting efficiency. After switching to the UDS010 diamond saw blade and following the correct selection and operation methods, they were able to reduce blade replacement costs by 25% and increase cutting efficiency by 20%. This case shows the significant user value that the UDS010 saw blade can bring.

Finally, it's crucial to emphasize safety. Users should wear appropriate protective equipment such as goggles and gloves. They should also follow the machine's safety instructions strictly. By adhering to safety regulations, users can prevent accidents and ensure a smooth cutting operation.

The UDS010 diamond saw blade, with its advanced technology and excellent performance, offers construction and metal - processing users an efficient, cost - effective, and safe cutting solution. If you want to improve your cutting efficiency and reduce costs, click here to learn more about the UDS010 saw blade and start your high - quality cutting journey today!